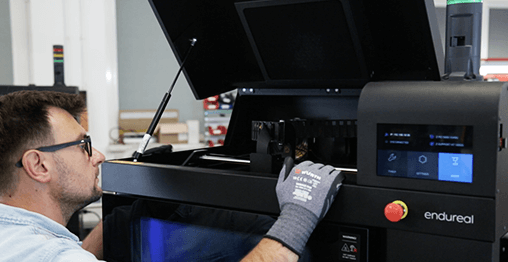

Zortrax Endureal industrial 3D Printer features advance thermal management for high performance polymers. The filament temperature is tightly controlled throughout the printing process in order to achieve the best precision and optimum mechanical material properties.

Free lifetime remote support on all products

Ask us about our discounts for education

3rd Generation industrial 3D Printer. the Zortrax Endureal features advance thermal management for high performance polymers. The filament temperature is tightly monitored and controlled throughout the printing process in order to achieve the best precision and optimum mechanical material properties.

High Temperature Extruder- Works at sustained temperature of 480°C

Heated Build Chamber- temperature in the build chamber can reach 200°C for engineering materials requiring high temperatures.

Heated Build Platform- Capable of reaching 220°C to ensure parts remain stable to the platform.

Auto Annealing- Features an automatic annealing function which can be carried out after printing has finished to achieve the highest material mechanical properties available.

Advance Thermal Shielding- The extruder compartment is always kept a ta safe operating temperature to ensure filament transmission is uninterrupted.

Heated Filament Compartment- Secure, closed environment for the filament spools so they can be kept at optimum printing temperature.

Blackout Response System- Endureal can detect when there has been a power outage and will use the energy it has stored in the built in capacitors to save the exact position the print head was at. Once power has been resumed the build can carry on from that exact place.

Remote Printing Monitoring- Featuring a heat resistant camera in the build chamber, the Endureal can provide live video streaming of the print progress.

Advance Filament Sensor- Automatically detects when filament is jammed or used up using multiple sensors. These sensors can also tell you if you have enough filament loaded to complete your job.

Temperature sensors measure temperature of crucial components

Capacitive sensor measure and check calibration of build platform and nozzles

Optical sensors to check the extruders position

Fan stop sensor automatically detects if a fan disconnects or stops working

Extruder sensor detects the extruders are connected and working properly

Dual extrusion system capable of printing in high temperature filaments. These extruders are thermally shielded from the build chamber for safe operation. The Endureal is compatible with both dual and single extrusion modes.

Load Bearing Components such as in Mechanical Engineering, Aerospace and Automotive- This part was printed in Z-PEI 9085 and has properties comparable to aluminium.

High Wear Resistance parts such as in Mechanical Engineering, Aerospace and Automotive- This part was printed in Z-PEEK and is end use.

Great Strength to Weight ratio- this part was printed in PEEK where the high strength to weight ratio makes it idea for sliding parts.