Free lifetime remote support on all products

Ask us about our discounts for education

Contact us to arrange a viewing

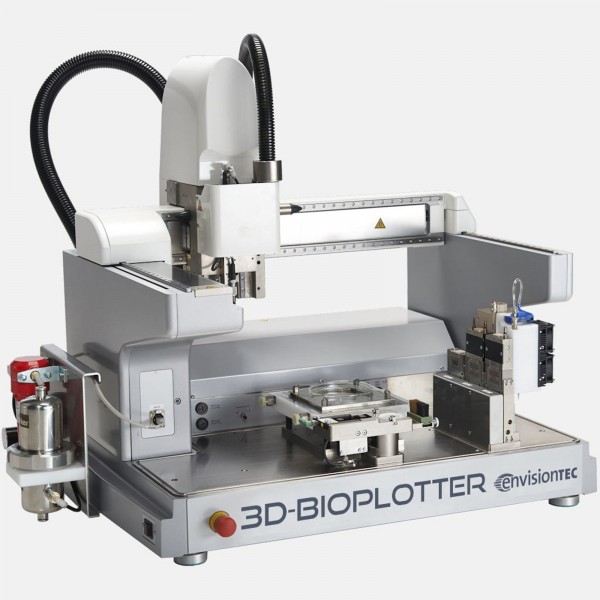

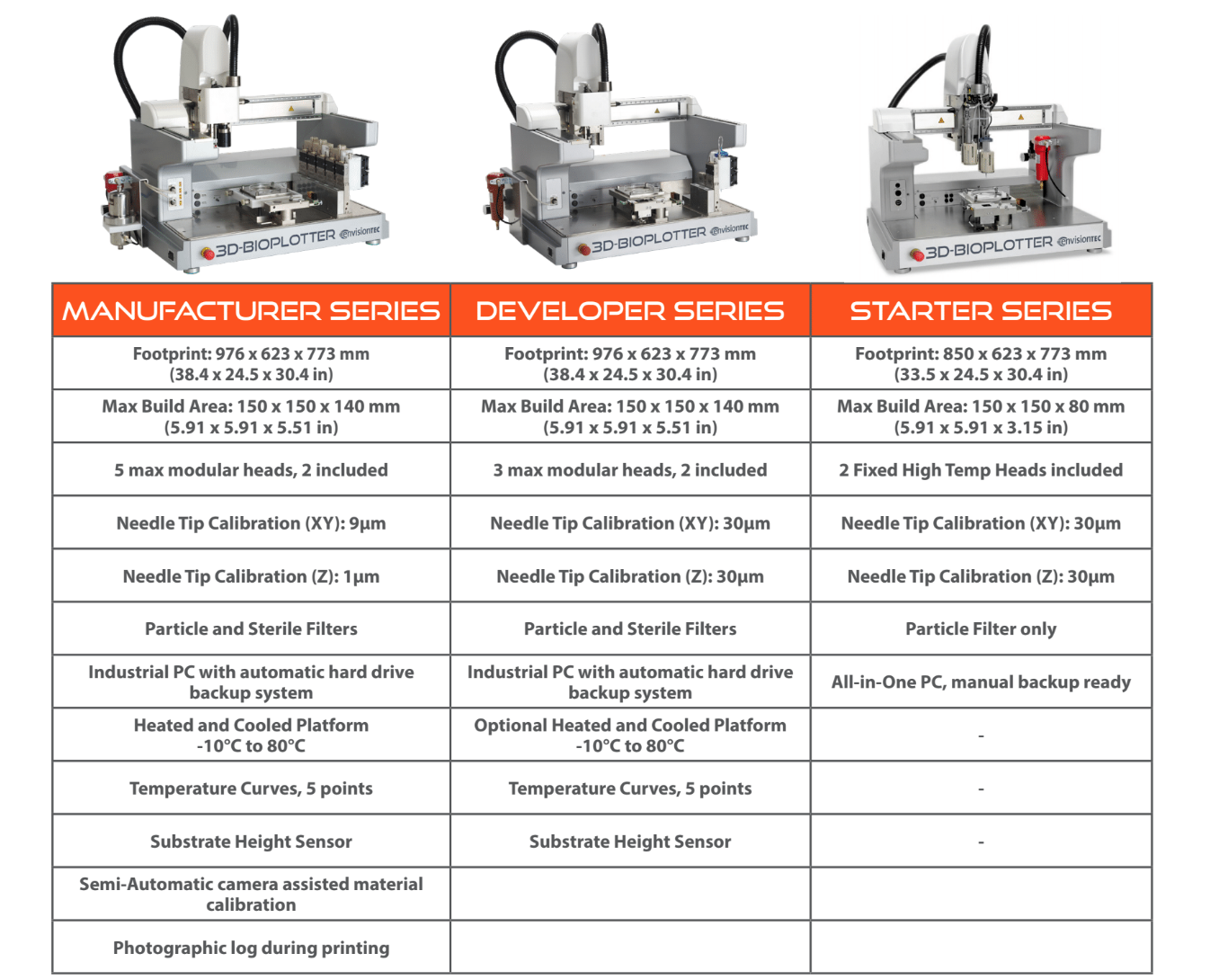

Three levels of functionality in the series: Starter, Developer, and Manufacturer

Starter Series: For users new to tissue engineering, the starter series is also ideal for applications in parallel material processing and automation. With the same basic hardware and software, the Starter series comes with 2 fixed high-temperature heads and no modular capability and platform temperature control and is not upgradeable like the Developer and Manufacturer.

Developer Series: Designed for research groups new to tissue engineering as well as specialised use, the Developer series has the same hardware and software as the Manufacturer series, but lacks more involved functionality.

Manufacturer Series: With the highest level of functionality and most advanced features, the Manufacturer series is a versatile biomedical tool for use of processing the largest variety of biomaterials. It features a built-in camera for enhanced needle calibration and temperature controlled build platform and sensor ports.

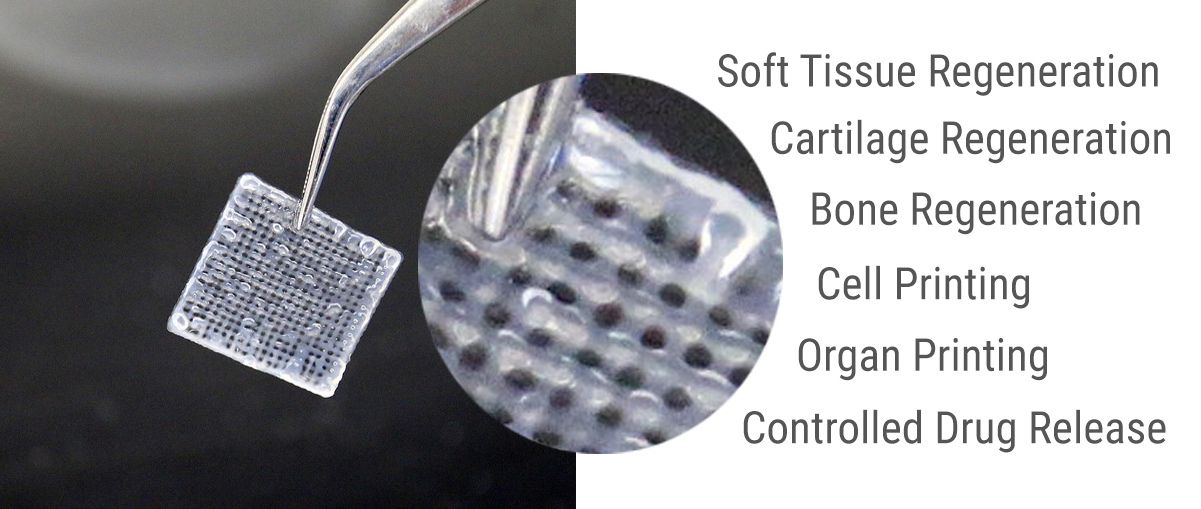

THE BIO-PLOTTER PROCESS:

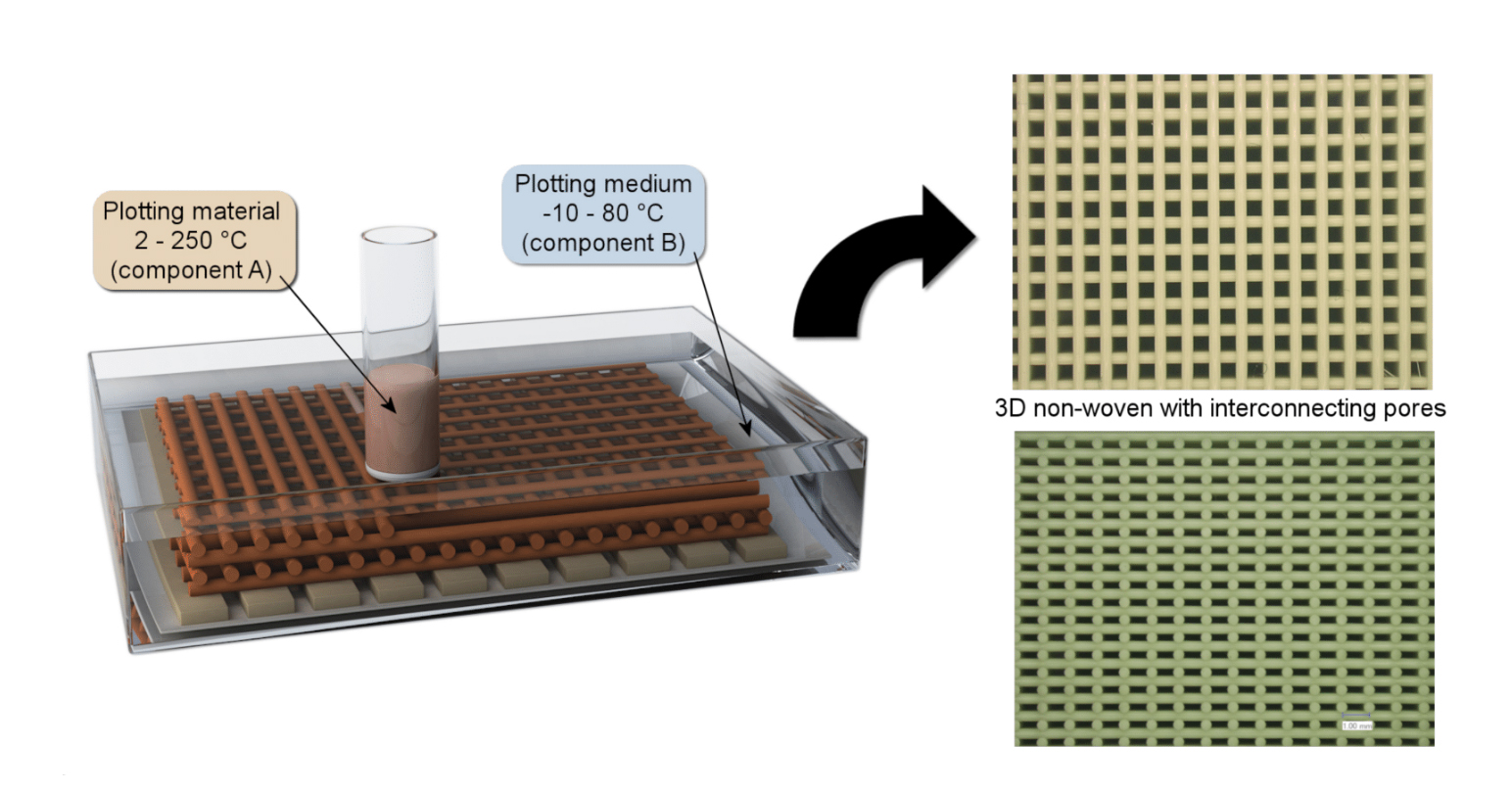

A simple process: A liquid, melt, paste or gel is dispensed from a material cartridge through a needle tip from a 3-axis system to create a 3D object.

One single requirement: The material to be used must, through a physical or chemical reaction, solidify.

Explore countless possibilities: The widest range of materials of any 3D printing technology can be processed.