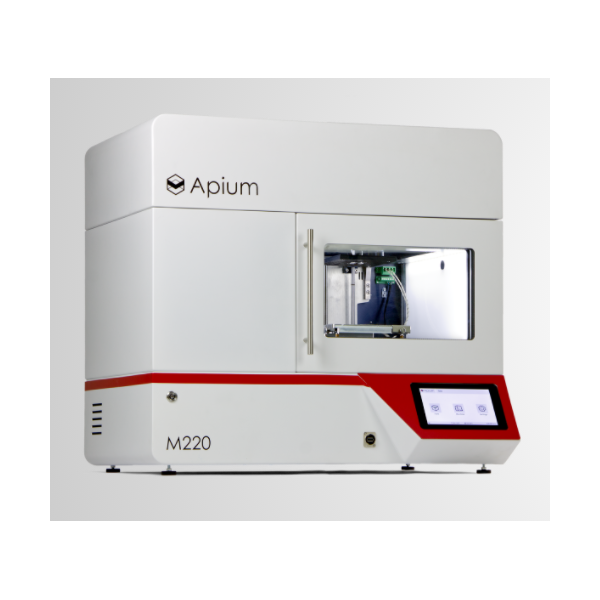

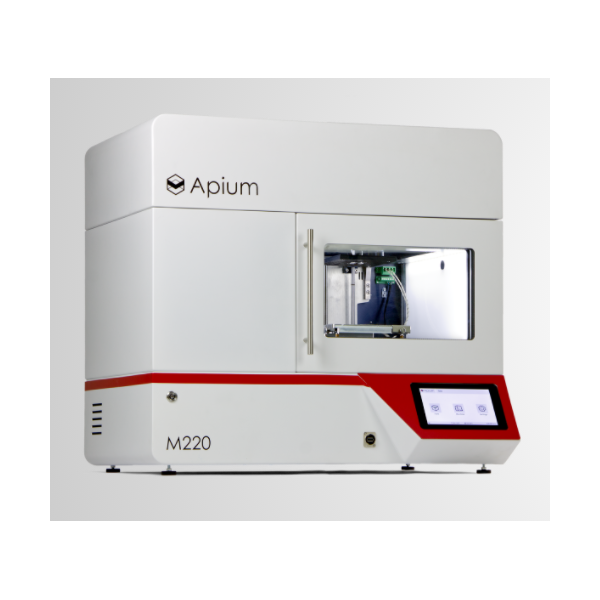

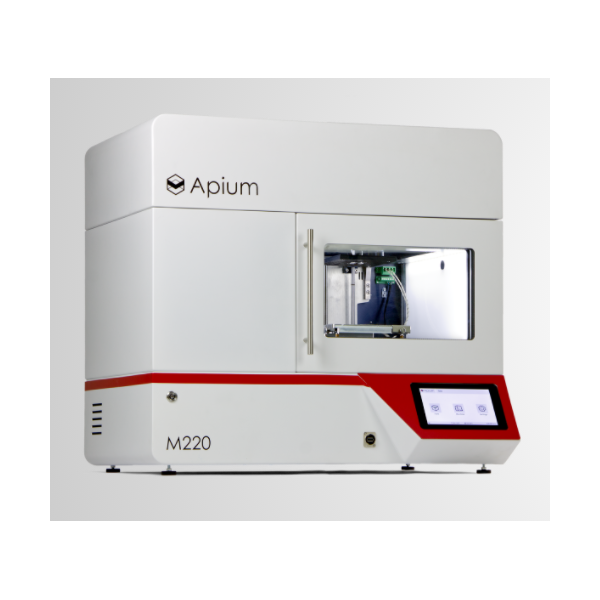

The Apium M220 Printer is the first in the world to be specifically designed for the manufacturing of medical products and implants made from the 3D printing material PEEK. This printer is a cost-effective solution to manufacture customised implants.

Spørg os om vores rabatter til uddannelse

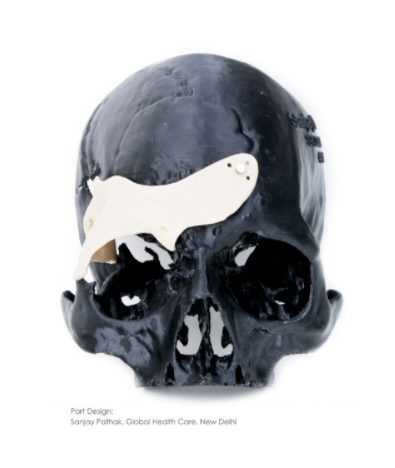

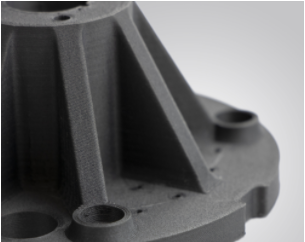

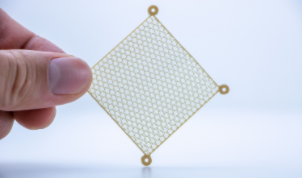

The Apium M220 Printer by Apiumtec is designed for manufacturing parts in PEEK material, which is a strong and highly chemical resistant 3D printing material perfect for printing customised implants. The PEEK material available from Apiumtec for use with this machine has received ISO 10993 certification for biocompatible medical devices. The Apium M220 with its advanced innovative technology will print to the highest quality standards. The quality of the prints gives the possibility to produce patient specific prostheses and implants quickly, without affecting the PEEK's biocompatibility and sterilisation properties. More complex geometries can be created using radiological imaging as input. Within a few hours the patient specific data has been manufactured, sterilised and sent off for the patient. This speedy process is possible, thanks to the integrated filter system of the machine. The control software further supports this machines compatibility with the medical sector. To prevent any mismanagement or sub-standard products, the software traces and labels every production batch, to document any mistakes immediately. The combination of the Apium M220 and PEEK filament cannot only be used to produce the best-fitting prosthetics and to immitate the human bone structure, it can also be used to print medical equipment, such as surgical tools that come in contact with patients and therefore require medical certification.

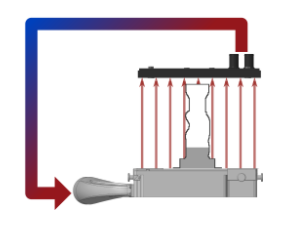

The Apium M220 provides a sterile printing environment through it's hot-air filter system. This system analyses the component geometry and adapts the heating power as such, to achieve the optimum energy input as needed. Additionally, the air flow enclosing the component is filtered in an almost fully particle-exclusive circuit.

The M220 3D printer offers a higher feed force compared to the previous models - around four times higher - this enables the machine to deliver a precise material flow. The extruder was developed to guarantee flexibility and durability. To ensure 100% safety in using the printed parts for implants, every component in contact with the printing material, is made of medically compatible material, such as PEEK, titanium, 316 L steel and PTFE.

The PEEK material used in printing with this machine was tested for it's biocompatibility in collaboration with Evonik to achieve ISO certification and allow medical devices up to Class III to be manufactured.

The printing process is continuously monitored on this machine by the integrated camera system, the temperature recording and servomotors. This allows the printer to intervene automatically in case anything isn't going smoothly.

Integrated calibration routines ensure consistent component quality. The software automatically informs users about upcoming maintenance operations and helps through the procedures step-by-step.

All important data concerning the printing process will automatically be provided in a PDF protocol. The integrated user administration prevents unwanted access. For user security and data protection, there is no cloud based solution.

The Apium M220 printer comes with an integrated software, specifically designed for this printers hardware and optimised for processing high-performance polymers. The interface is easy to use and users can check the progress of their print at anytime.

| Build Size | 132 x 132 x 120 mm |

| Printer Size | 850 x 685 x 675 mm |

| Weight | 67 kg |

| Machine Accuracy | 10 μm horizontically, 3 μm vertically |

| Nozzle Diameter | 0.2 - 0.8 mm |

| Layer Thickness | 0.05 - 0.8 mm |

| Wall Thickness | > 250 μm |

| Printhead-Temp. | Up to 540° C |

| Hot-Air Filtered System | Up to 280° C |

| Printbed Material | Stainless Steel 316 L |

| Power Consumtion | 600 W max. |

| Noise Emission | < 70 dB(A) |

| Data Formats | STL, OBJ, G-Code |

| Connectivity | WLan, Ethernet |