Applying 3D Printing to the Dental Industry

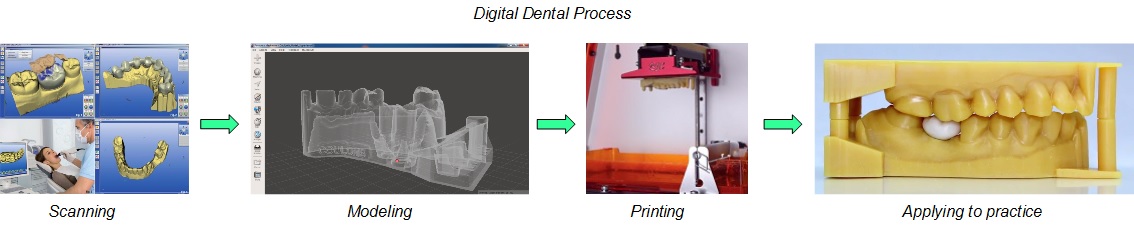

In dentistry and dental surgery the use of 3D scanning and printing is already becoming more often utilized in order to create the actual pieces used by orthodontists, dentists and dental surgeons.

3D printing and modeling can be used in many different ways when looking at it from a dental perspective. For dental surgeons, guides can be printed for use when drilling and/or cutting. The printed guides, when compared to casts, are more accurate with less deviation. Using CAD software, prosthodontists have the ability to create crowns and bridges, implant abutments and bridge structures.

More Options

Prosthodontists have the option to print in castable resins or waxes, or they can print the models directly using metal materials. However, printing in resin or wax is preferred because of multiple advantages: reduced post-processing time, widely available casting alloys and no requirement for costly equipment to process materials directly.

When 3D scanners are used to scan dental models, the scans will not simply be stored digitally but later they can be used to print a physical model.

Using software like Invisalign®, orthodontists can plan their patient’s treatment ahead of time and provide a visual image of the teeth being aligned correctly. Later, orthodontists can use 3D printing to create a stone model for every intermediate step until the perfect position for the teeth is achieved.

These stone models help to create the aligner that will eventually be thermoformed. Orthodontists also have the opportunity to create more comfortably fitting bite splints and night guards by utilizing their scanned models.

Around these stone models, the aligner can be thermoformed. Bite splints, or night guards, can also be created directly around a scanned model of the teeth causing them to be more comfortable and fit perfectly.

The Equipment

Different equipment is used for different 3D scans and prints. Stone models can be made using FDM printers like the Cubicon 3DP - 110F. The aligners, abutments and implants are mostly created using SLA or DLP printers like the B9Creator and the MiiCraft 125 because the final product is smaller, more intricate and castable.

Intraoral scanners like 3Shape Trios, CEREC Omnicam, iTero Element and Carestream CS3600 are used to make scans of the patients' jaws that further be enhanced using software packages. InVesalius is used by most top orthodontists to make a prediction about further treatment. Other software such as ExoCAD, Renishaw DS or inLab SW-15 can be used to model the crowns and bridges, while Implant3D's software is used to create implants and abutments.

Comments

Leave your comment