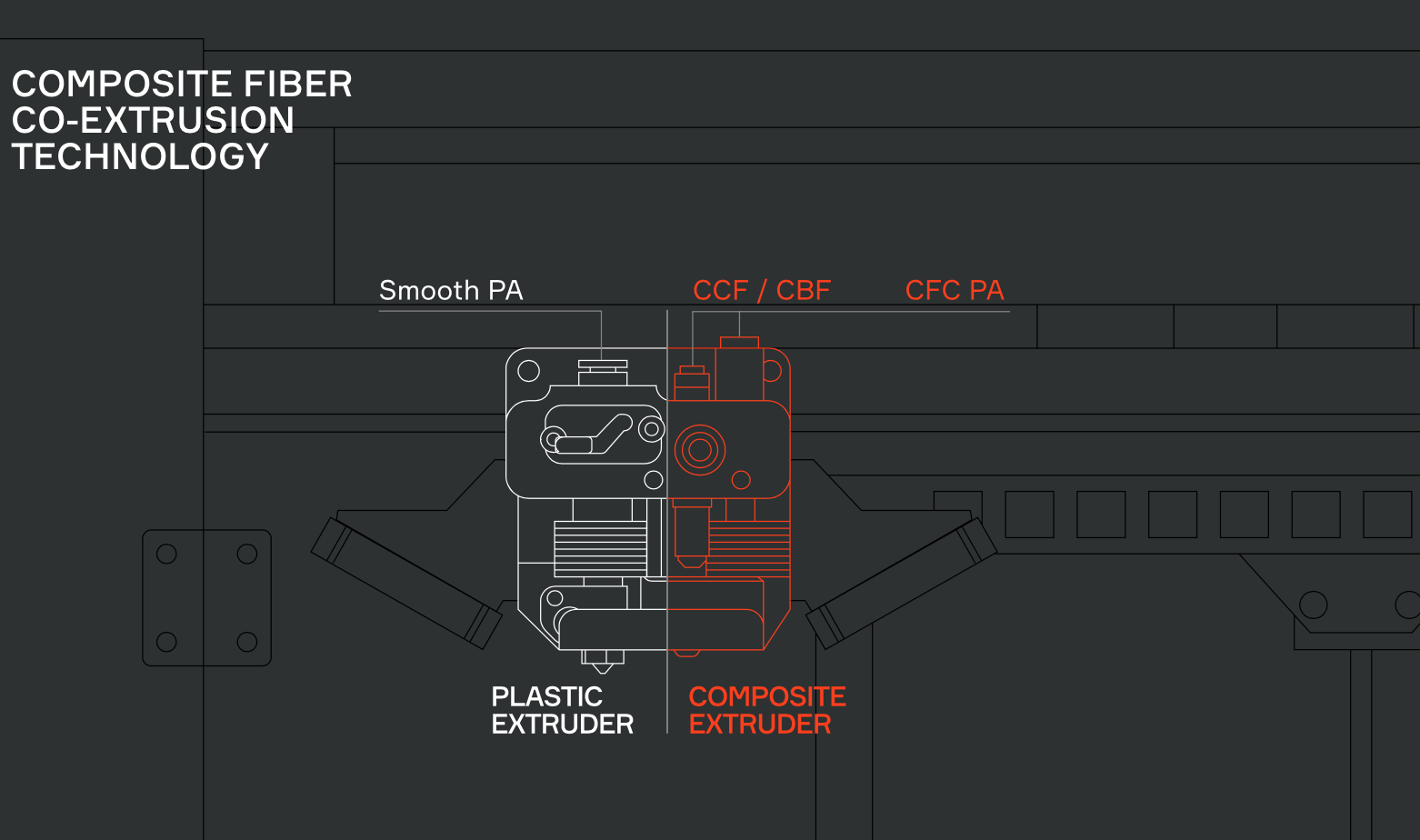

CFC PA by Anisoprint is specifically designed to be used with their continuous fiber co-extrusion process (CFC). This premium polyamide filament has a low moisture absorption rate and lower viscosity for improved co-extrusion with carbon fiber strands.

Kostenloser lebenslanger Remote-Support für alle Produkte

Fragen Sie uns nach unseren Bildungsrabatten

CFC PA is a new material developed by Polymaker and presented by Anisoprint for continuous fiber coextrusion. Its purpose is to secure a traction between its fiber layers by acting as a grid material with low viscosity. These additional properties allow CFC PA to have a superior part performance. Furthermore, CFC PA also has a rapid cooling and solidification system which increases the accuracy of their fiber placement.