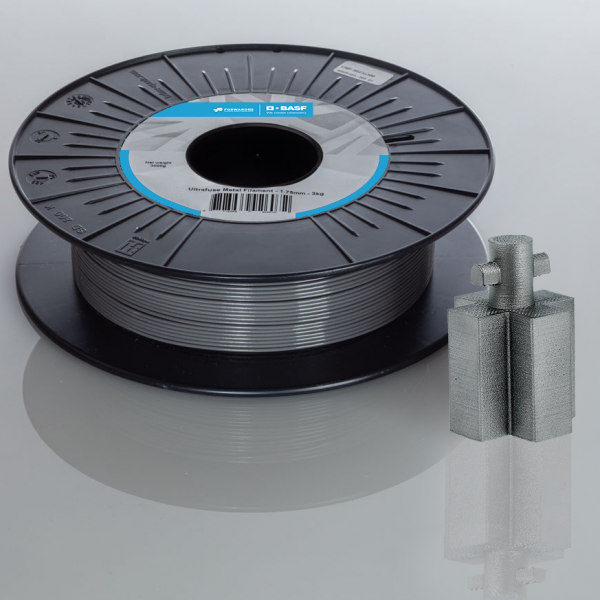

BASF Ultrafuse 17-4 PH Stainless-steel composite filament is for the production of metal components in 17-4 stainless steel on standard FFF (fused filament fabrication) 3D printers. This stainless steel can be fully heat treated to achieve high levels of strength and hardness.

Free lifetime remote support on all products

Ask us about our discounts for education

.png)

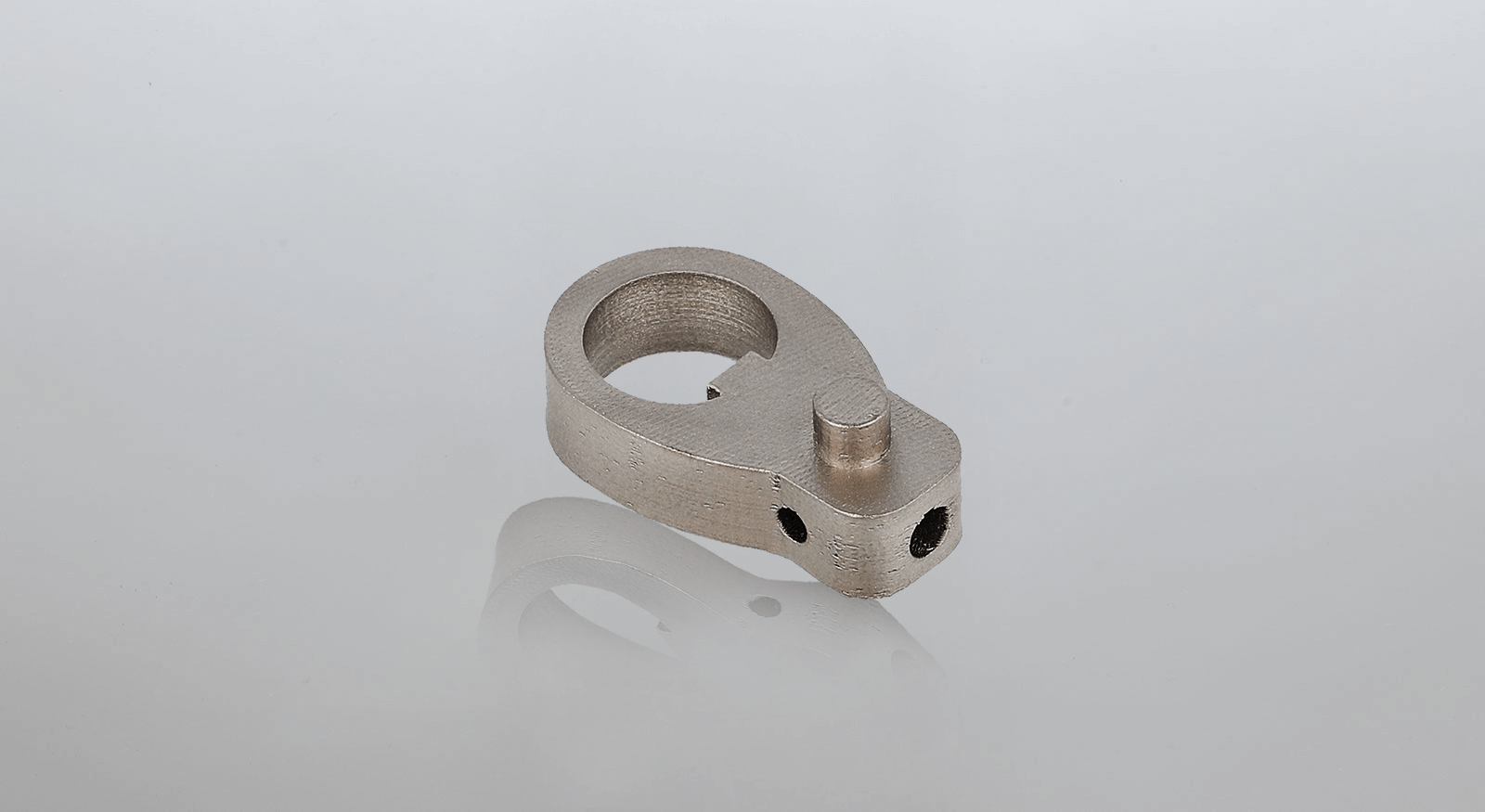

BASF Ultrafuse 17-4 PH Stainless-steel composite filament is for the production of metal components in 17-4 stainless steel on standard FFF (fused filament fabrication) 3D printers. This stainless steel can be fully heat treated to achieve high levels of strength and hardness. This filament is perfect for Petrochemistry, Aerospace, Automotive and Medical industries. Parts made from BASF Ultrafuse 17-4 PH keep their final properties through a catalytic debinding and sintering process known from traditional Metal Injection Moulding.

Works with standard FFF 3D Printers

Material and mechanical properties comparable to Stainless-steel

Geometric freedom with 3D Printing

Wide range of post-processing options for green parts

Tooling

Jigs and fixtures

Series production

Functional parts and prototypes