Home

Delta WASP 2040 Clay

Specifically designed and developed for ceramics 3D printing, the Delta WASP 2040 Clay 3D Printer is a fundamental desktop tool for any professional in the ceramics or design industry.

Snapmaker Filter Cartridge for Air Purifier (2 pcs)

Breathe easier inside your work area with this 2-pack of Filter Cartridges for Snapmaker 2.0 Air Purifier from Snapmaker. Each cartridge includes five layers of filtration and are arranged in such a way as to maximize its lifespan, which is approximately 3 months per cartridge. All five layers of filtration can trap and absorb PM0.3- to PM10-sized particles, as well as VOCs and odors—essentially what is emitted during 3D printing and laser engraving with the Snapmaker 2.0.

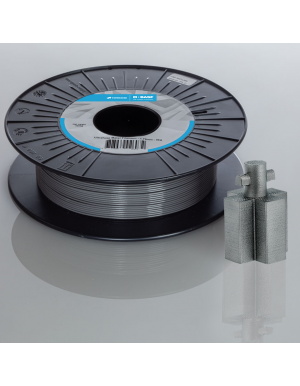

BASF Ultrafuse 17-4 PH

BASF Ultrafuse 17-4 PH Stainless-steel composite filament is for the production of metal components in 17-4 stainless steel on standard FFF (fused filament fabrication) 3D printers. This stainless steel can be fully heat treated to achieve high levels of strength and hardness.

Loctite 3D MED412 HDT40 High Impact

Available in either Ultra Clear or White. The Henkel Loctite MED412 medical resin is a strong, durable material with excellent elongation, impact strength and surface finish. Ideal for single use medical devices.

Available in white and clear.

Polymaker PolyMide PA12-CF 500g

PolyMide PA12-CF is a carbon fibre reinforced PA12 filament. With low moisture sensitivity the filament features excellent mechanical and thermal properties. Applications include manufacturing tooling.

Nexa3D NXE 400

Nexa3D xCURE Post-Curing Unit

The xCURE from Nexa3D is the perfect post-curing solution to ensure you achieve optimum material properties. Designed to cure an entire build volume from the Nexa3D NXE 400 in one go. Featuring three curing modes; UV only, Heat only and UV + Heat and pre-set individual resin curing profiles, the Nexa3D xCURE is the perfect solution for post curing your parts.

Nexa3D xWASH Post-Processing Unit

Nexa3D xWASH is a post-processing washing station designed specifically to clean resin parts from the Nexa3D NXE 400. You can wash two entire build volumes simultaneously thanks to the xWASH large capacity. Choose to wash your parts while still attached to the build volume or as individual parts in the basket. With a simple, user friendly interface to help set parameters such as timer length, agitation speed and direction, the Nexa3D xWASH is a powerful and consistent part washing solution.

Phrozen Sonic Mega 8K - PFA (nFEP) Film

Durable and long-lasting FEP film for the Phrozen Sonic Mega 8K 3D printer.

LOCTITE 3D | IND405 HDT50 High Elongation - 1 Litre

Henkel LOCTITE 3D IND405 HDT50 High Elongation is a tough, high impact resistant resin with a great surface finish. An extremely durable material which excels in applications such as tool production, manufacturing aids and final parts.

Available in black and clear.